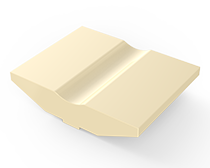

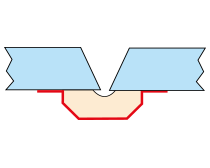

The ceramics backup tape is made of materials with a strong heat resistance and a durability that can withstand thermal shocks during high-temperature welding operation.

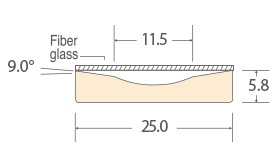

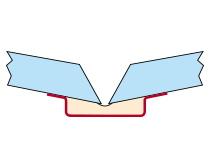

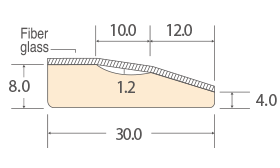

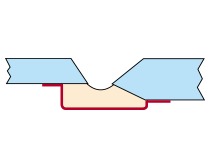

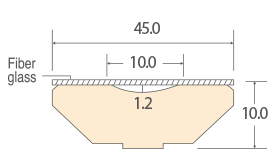

Glass fiber is used to prevent the misalignment of members and form clean and even back beads.

Backing materials for SAW are used to:

* Ensure high-efficiency welding, with the current carrying capacity varying from 800 A to 1,660 A.

* Form back beads that are the same to those of the base metal with the completion of welding, and a high welding reliability is achieved as the back bead defects rarely occur.

* Significantly speed up welding operation, thus contributing to productivity improvement.

* Improve poor workplace environment caused by welding arc light and fumes, and ensure easy and safe detachability of backing materials.